|

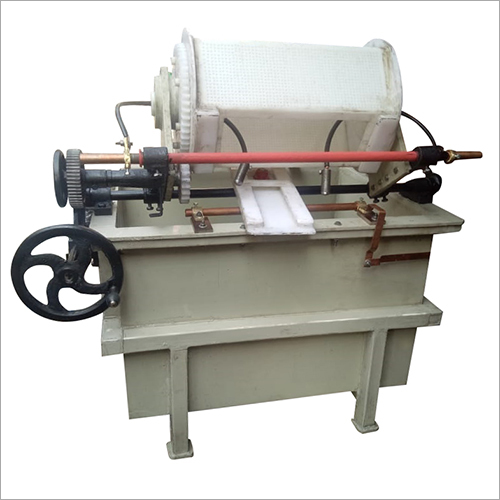

CAUSTIC Barrel Machine

Price 28000.0 INR/ Piece

CAUSTIC Barrel Machine Specification

- Material

- Mild Steel

- Condition

- New

- Technology

- Latest PLC Control

- Dimension (L*W*H)

- 2100 mm x 1050 mm x 1800 mm Millimeter (mm)

- Power Mode

- Electric

- Voltage

- 380 V Volt (v)

- Power Consumption

- 7.5 kW Kilowatt (kW)

- Engine Configuration

- Single phase motor drive

- Application

- Barrel and Drum Cleaning/Processing

- Weight

- 1250 kg Kilograms (kg)

- Coating Type

- Anti-corrosive powder coating

- Usage Area

- Chemical, Pharmaceutical, and Industrial Plants

- Control Panel

- Digital Touch Control

- Noise Level

- Less than 65 dB

- Drum Capacity

- Up to 250 Liter Barrels

- Automation Grade

- Fully Automatic

- Structure

- Heavy Duty Welded Frame

- Color

- Industrial Blue/Grey

- Safety Features

- Emergency stop and interlock

- Surface Treatment

- Rust-proofed and Painted

About CAUSTIC Barrel Machine

Caustic Barrel Machine Description

The Caustic Barrel Machine is designed for efficient chemical cleaning, stripping, and surface treatment of metal components using caustic solutions. Engineered for industrial environments, this machine provides uniform processing through controlled rotation, ensuring every part is evenly exposed to the cleaning agent for consistent results.

Built with high-strength, corrosion-resistant materials, the Caustic Barrel Machine offers exceptional durability and long service life, even under continuous exposure to harsh chemicals. Safety features such as sealed construction, robust locking mechanisms, and efficient drainage systems help ensure safe and reliable operation.

Ideal for foundries, metal finishing plants, automotive workshops, and manufacturing industries, this machine is suitable for removing grease, oil, oxides, paint, and other stubborn contaminants. It enhances productivity while maintaining high standards of cleanliness and surface preparation.

Key Features and Construction

Engineered with a heavy-duty welded frame, the CAUSTIC Barrel Machine boasts a rust-proof, anti-corrosive powder-coated surface, making it suitable for demanding industrial environments. Its highly efficient electric drive reduces operating noise to below 65 dB, supporting a cleaner workplace. The integration of the latest PLC control technology and a user-friendly digital touch panel ensures heightened precision and ease of use.

Safety and Automation Advantage

Safety is at the forefront, featuring an emergency stop and interlock system that guarantee secure operation. Fully automatic processing streamlines drum and barrel cleaning tasks, minimizing labor and reducing downtime. These advancements make the machine ideal for chemical, pharmaceutical, and industrial applications with stringent safety and hygiene standards.

FAQs of CAUSTIC Barrel Machine:

Q: How does the CAUSTIC Barrel Machine operate for cleaning barrels and drums?

A: Operation is fully automated via a digital touch control panel. Simply load the drum (up to 250 liters), set your cleaning parameters, and initiate the cycle. The machine employs advanced PLC technology for consistent and effective barrel or drum cleaning, minimizing manual intervention.Q: What are the main benefits of using this barrel machine in industrial plants?

A: The main advantages include enhanced cleaning effectiveness, labor saving, reduced turnaround time, low operating noise, and strict adherence to modern safety protocols. This ensures plant operations remain efficient and workers remain safe.Q: When should the CAUSTIC Barrel Machine be used in the production process?

A: The machine is ideally used before refilling barrels or at the end of a production cycle to ensure all containers meet hygiene and contamination control standards, vital for industries such as chemical and pharmaceutical manufacturing.Q: Where can this machine be installed and utilized?

A: It is designed for easy setup in a range of environments, including chemical, pharmaceutical, and other industrial plants throughout India. The robust design supports both indoor and sheltered outdoor placements.Q: What is the typical process for cleaning a drum with this machine?

A: Place the drum/barrel onto the loading position, select the required cleaning cycle via the digital panel, and let the machine automatically handle the washing, rinsing, and drying as per setupensuring superior cleaning without the need for manual handling.Q: How does the design ensure operator safety during operation?

A: The machine features an integrated emergency stop and interlock system that halts operations immediately if safety is compromised, thereby reducing the risk of accidents and ensuring compliance with industrial safety standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Barrel Polishing Machine Category

MS +Ruber+ PVC PLATING BARELL

Price 70000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Engine Configuration : Single Motor Drive

Coating Type : Barell Plating

Material : Mild Steel (MS), Rubber, PVC

Dimension (L*W*H) : Custom/Standard (typically ranges depend on model, check product details) Millimeter (mm)

High Speed Barrel Polishing Machine

Price 70000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Engine Configuration : Single Phase Induction Motor

Coating Type : Powder Coated

Material : Mild Steel

Dimension (L*W*H) : 1100 mm x 900 mm x 1200 mm Millimeter (mm)

|

S. K. ENGG. WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry