|

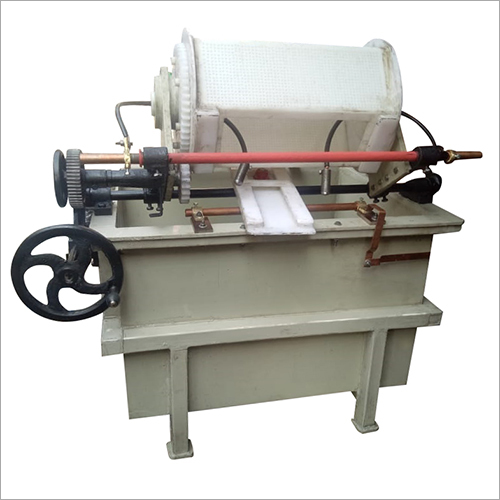

High Speed Barrel Polishing Machine

Price 70000.0 INR/ Piece

High Speed Barrel Polishing Machine Specification

- Material

- Mild Steel

- Condition

- New

- Technology

- High-Speed Rotational Barrel

- Dimension (L*W*H)

- 1100 mm x 900 mm x 1200 mm Millimeter (mm)

- Power Mode

- Electric

- Voltage

- 220-240 V Volt (v)

- Power Consumption

- 2.5 kW Kilowatt (kW)

- Engine Configuration

- Single Phase Induction Motor

- Application

- Metal Surface Finishing, Deburring and Polishing

- Weight

- 430 kg Kilograms (kg)

- Coating Type

- Powder Coated

- Barrel Material

- High-Grade Polypropylene Lining

- Mobility

- Mounted on Heavy-Duty Wheels

- Finish Quality

- Mirror/Semi-Mirror Finish

- Working Speed

- 1800 RPM

- Polishing Cycle Time

- 10-30 Minutes (Adjustable)

- Safety Features

- Overload Protection & Emergency Stop

- Accessories Included

- Media Separator, Polishing Compound Hopper

- Barrel Capacity

- 250 Liters

- Control Panel

- Digital Automatic Timer

- Noise Level

- Low Noise Operation (<72 dB)

About High Speed Barrel Polishing Machine

High Speed Barrel Polishing Machine Description

The High Speed Barrel Polishing Machine is engineered for efficient, precision surface finishing across a wide range of metal and non-metal components. Designed to deliver rapid polishing, deburring, and edge-smoothing, this machine uses high-speed rotation to achieve consistent, high-quality results in significantly less time than traditional methods.

Built with a durable barrel, reinforced structure, and advanced vibration-free technology, it ensures stable operation, reduced noise, and extended service life. Ideal for manufacturing, jewelry, automotive, and hardware industries, this machine supports various media types and can be customized for different finishing requirements.

Whether for mass production or detailed craftsmanship, the High Speed Barrel Polishing Machine provides superior performance, reliability, and a smooth, professional finish every time.

Effortless Operation and High-Quality Finish

Experience seamless operation with automatic digital controls and a barrel capacity of 250 liters, ensuring each run achieves a consistent mirror or semi-mirror finish. The high-speed rotational barrel technology, backed by a sturdy mild steel frame, enhances process efficiency while minimizing manual intervention.

Advanced Safety and User Convenience

Safety is paramount, with overload protection and an emergency stop feature incorporated into the control system. The machines heavy-duty mobility wheels and ergonomic design make it easy to relocate and operate, offering flexibility for a range of industrial environments.

Comprehensive Accessory Set & Durable Build

Every machine comes with essential accessories, including a media separator and polishing compound hopper for swift preparation and post-processing. The high-quality polypropylene lining ensures long barrel life and protects delicate surfaces. Powder-coated for resilience, this unit is designed to withstand demanding operational cycles.

FAQs of High Speed Barrel Polishing Machine:

Q: How does the barrel polishing process work in this machine?

A: The machine uses high-speed rotational barrel technology, spinning the 250-liter polypropylene-lined barrel at 1800 RPM. Parts are combined with media and polishing compounds, and as the barrel rotates, friction and tumbling actions remove burrs and polish surfaces to a mirror or semi-mirror finish.Q: What materials can be processed with this polishing machine?

A: It is primarily designed for metal surface finishing applications, effectively processing components made from steel, aluminum, brass, or similar metals. The system delivers optimal results for deburring, polishing, and enhancing the appearance of various metal parts.Q: When is it recommended to use the adjustable cycle time feature?

A: Adjust the polishing cycle (between 10 to 30 minutes) based on part size, material hardness, and desired finish quality. Shorter cycles are suitable for light deburring, while longer times are ideal for achieving a highly polished, mirror-like effect.Q: Where can this machine be installed and operated effectively?

A: The machines compact dimensions (1100 mm x 900 mm x 1200 mm), low noise operation, and mobility wheels allow installation in diverse environments such as factories, workshops, and manufacturing facilities across India, especially where efficient, clean, and quiet operation is desired.Q: What are the main safety features included in the machine?

A: User safety is ensured with built-in overload protection and an emergency stop button on the digital control panel, providing immediate operation halt in the event of overloads or emergencies.Q: How is the mirror or semi-mirror finish achieved on metal surfaces?

A: The combination of high-speed rotation, quality polishing compounds, and specialized media produces consistent friction and motion, thoroughly smoothing and refining the metal surfaces. Precise cycle control ensures the desired finish is attained every time.Q: What is the benefit of the media separator and polishing compound hopper provided?

A: The media separator allows for quick separation of finished components from the polishing media after the cycle, streamlining workflow and reducing handling time. The polishing compound hopper provides convenient, measured dispensing to ensure optimal results and prevent wastage.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Barrel Polishing Machine Category

MS +Ruber+ PVC PLATING BARELL

Price 70000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Technology : Other, Electroplating Barrel Technology

Power Mode : Electric

Voltage : 220380 V Volt (v)

Weight : Approximately 100350 kg (varies as per design/model) Kilograms (kg)

CAUSTIC Barrel Machine

Price 28000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Technology : Other, Latest PLC Control

Power Mode : Electric

Voltage : 380 V Volt (v)

Weight : 1250 kg Kilograms (kg)

|

S. K. ENGG. WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry