Most Popular Products

|

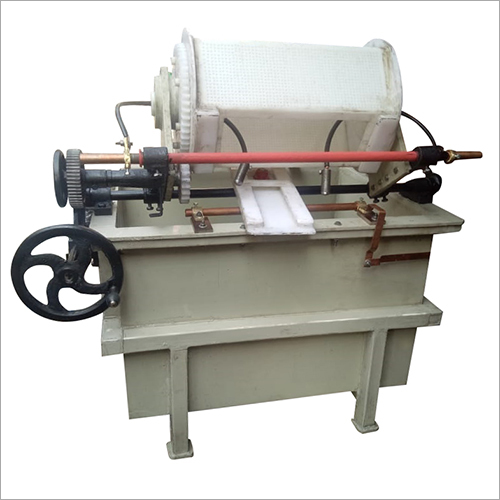

MS +Ruber+ PVC PLATING BARELL

Price 70000.0 INR/ Piece

MOQ : 1 Piece

MS +Ruber+ PVC PLATING BARELL Specification

- Material

- Mild Steel (MS), Rubber, PVC

- Condition

- New

- Technology

- Electroplating Barrel Technology

- Dimension (L*W*H)

- Custom/Standard (typically ranges depend on model, check product details) Millimeter (mm)

- Power Mode

- Electric

- Voltage

- 220-380 V Volt (v)

- Power Consumption

- 2-5 kW (varies by model) Kilowatt (kW)

- Engine Configuration

- Single Motor Drive

- Fuel Tank Capacity

- Not Applicable (Electric Powered) Liter (L)

- Application

- Electroplating of small parts, fasteners, hardware, and components

- Weight

- Approximately 100-350 kg (varies as per design/model) Kilograms (kg)

- Coating Type

- Barell Plating

- Drum Capacity

- 15-50 liters depending on model

- Features

- Leakproof design, corrosion resistant, efficient mixing

- Opening Type

- Top and side loading for easy access

- Barrel Rotation Speed

- 2-10 RPM adjustable

- Frame Construction

- MS with anti-rust treatment

- Maintenance

- Low maintenance, easy to clean and operate

- Control System

- Digital/Manual Control Panel

- Noise Level

- Low noise operation

- Barrel Material

- High grade PVC for corrosion resistance

- Usage Area

- Industrial plating workshops

About MS +Ruber+ PVC PLATING BARELL

High-quality plating barrel designed for efficient and uniform surface finishing. Manufactured using a durable combination of Mild Steel (MS), Rubber lining, and PVC construction, this barrel ensures excellent chemical resistance, long service life, and smooth rotation for consistent polishing and electroplating results. Ideal for metal finishing industries requiring reliable performance, corrosion protection, and precise polishing output.Durable Construction and Advanced Technology

This plating barrel features a combination of high-grade PVC, rubber, and mild steel with special anti-rust treatment, ensuring excellent resistance to corrosion and a long operational lifespan. Integrated with state-of-the-art electroplating barrel technology, it delivers consistency in performance and efficient mixing of components, ideal for demanding industrial environments.

Designed for Convenience and Efficiency

Offering both top and side loading options, the barrel allows easy access for loading and unloading materials. The adjustable rotation speed and choice of digital or manual control panels provide operators with precise, user-friendly control. With a leakproof and low-maintenance design, the barrel supports efficient operation with minimal downtime.

FAQs of MS +Ruber+ PVC PLATING BARELL:

Q: How does the adjustable rotation speed benefit the electroplating process?

A: The adjustable rotation speed (210 RPM) ensures optimal agitation of parts during electroplating, allowing users to match the speed to the specific requirements of different materials and achieving uniform coating thickness.Q: What materials are used in the construction of the plating barrel and why?

A: The barrel is constructed from high-grade PVC for corrosion resistance, rubber for sealing, and mild steel (MS) treated against rust for structural strength. This combination ensures durability and reliable performance, even in harsh chemical environments.Q: When should I choose the MS + Rubber + PVC Plating Barrel for my workshop?

A: This barrel is an ideal choice when your facility requires efficient, low-noise, and corrosion-resistant equipment for electroplating small components, such as fasteners, hardware, and similar parts.Q: Where can this plating barrel be used effectively?

A: It is primarily designed for use in industrial plating workshops and facilities involved with surface treatment of metal components, especially in the manufacturing and hardware sectors.Q: What is the process for operating the plating barrel?

A: Operators load components through the top or side opening, set the rotation speed and duration via the control panel (digital or manual), and initiate the process. The electric motor ensures consistent rotation, while the leakproof and corrosion-resistant features maintain operational efficiency.Q: How easy is it to maintain and clean the plating barrel?

A: Maintenance is straightforward due to the barrels simple design and corrosion-resistant materials. The smooth internal PVC surface makes cleaning up after each batch quick and effortless.Q: What are the main benefits of using this electroplating barrel?

A: Users benefit from its leakproof construction, corrosion resistance, low operating noise, easily adjustable settings, and reduced maintenance, all contributing to efficient and cost-effective electroplating operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Barrel Polishing Machine Category

CAUSTIC Barrel Machine

Price 28000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Mode : Electric

Application : Barrel and Drum Cleaning/Processing

Weight : 1250 kg Kilograms (kg)

Material : Mild Steel

High Speed Barrel Polishing Machine

Price 70000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power Mode : Electric

Application : Metal Surface Finishing, Deburring and Polishing

Weight : 430 kg Kilograms (kg)

Material : Mild Steel

|

S. K. ENGG. WORKS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry